Specialty methacrylate resins

🔍 Search for specialty methacrylate products

Monomers

Designed to optimize end-use applications, our high performance resins are used by formulators as:

- reactive diluents

- building blocks for polymerization

Sartomer® products offer various chemical structures for advanced properties:

- Mono to multifunctional

- Linear to branched aliphatic

- Cycloaliphatic to aromatic

- Alkoxylated alkyl and aryl

- Dual functionalities (hydroxyl, allyl…)

Oligomers

These products are higher molecular weight molecules, providing key functional properties to the reactive systems and formulations. Sartomer offers market-leading:

- Urethane methacrylates

- Epoxy methacrylates

A core competence: specialty methacrylate chemistry

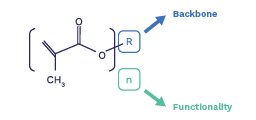

Arkema's high-performance methacrylate monomers and oligomers are designed for multi-mode curing, including EB, thermal peroxide and amine cure, as well as for engineered copolymers produced via solution, emulsion, or suspension routes. These versatile products offer a robust foundation for optical, structural, and flexible polymers, using MMA, methacrylic acid, and functional acrylate derivatives to adjust polarity, film formation, and property balance.

From mono-functional modifiers to multifunctional dimethacrylate oligomers, Sartomer® specialty methacrylates give formulators latitude to form tailored compounds, hybrid acrylic polymers, or specialty materials when comparing performance targets such as toughness, transparency, reactivity, or substrate bonding. This expertise in methacrylate chemistry enables differentiated applications across coatings, adhesives, composites and emerging sectors.

Solutions for superior performance properties

Sartomer® specialty methacrylate resins and methacrylate monomers have been developed to unlock advanced performance in high-value materials and formulated polymers. By tailoring functional content, reactive backbone, and molecular concentrations, these solutions deliver outstanding properties, including water, heat and solvent resistance, hardness, toughness, transparency, flexibility, and hydrophobic or water-soluble profiles.

Functional grades incorporating butyl, br, aromatics, esters, or urethane block structures allow formulators to fine-tune substrate bond, polarity, and mechanical durability. The ability to achieve precise combinations of reactivity and resistance makes Sartomer® specialty methacrylates an excellent platform for demanding applications such as high-performance coatings, adhesives, engineered polymers, and advanced composite materials across multiple industrial fields.

More information ...

-

Monomers Product Selector

-

Oligomers Product Selector

-

Photoinitiators Product Selector

Download our brochures

UV/LED Curing technologies with methacrylate monomers & oligomers

UV and LED curing technologies make extensive use of specialty methacrylate monomers and methacrylate oligomers as reactive building blocks to form advanced polymers, copolymers and engineered materials.

Leveraging controlled functionality, reactive content, backbone design and tailored concentrations, formulators can adjust key performance properties such as hardness, toughness, clarity, flexibility, adhesion and chemical resistance, using MMA, methacrylic acid and acrylate derivatives to balance reactivity and film durability.

3D Printing / Additive Manufacturing

In 3D printing and SLA/DLP additive applications, UV/LED-curable methacrylates enable high-resolution part fabrication with fast cure speed and excellent dimensional accuracy. Multifunctional grades, including dimethacrylate and urethane-based units, help form high crosslink density polymers, while functional substitution such as butyl, br, aromatics and esters allows finer tuning of elongation, modulus, abrasion resistance and post-processing behavior. These specialty building blocks support engineered compounds and photopolymer materials for dental AM, industrial prototyping and optical components, expanding the performance envelope of acrylics-based photopolymer systems.

Nail care

In professional and consumer Nail UV coatings and gel systems, methacrylate monomers provide viscosity control, flow, adhesion and touch feel, while methacrylate oligomers contribute toughness, scratch resistance, flexibility and lasting appearance. Using LED/UV curing kinetics and backbone variations, formulators develop polymer networks with improved wear durability and substrate bond, optimizing both optical aesthetics and user experience. These systems illustrate how methacrylates can be designed and developed into specialty polymers and copolymers for beauty, wellness and high-end finishing applications.